PHARMACEUTICALS

Your Partner in Pharmaceutical Manufacturing

Engineered for Purity, Validated for Compliance

For over 100 years, EcoProcess has been at the forefront of engineering excellence. For the pharmaceutical industry, we provide more than just equipment; we deliver peace of mind. Our systems are meticulously designed to meet the stringent demands of cGMP environments, ensuring product integrity, operational efficiency, and unwavering compliance. From API synthesis to solvent recovery, partner with EcoProcess to optimize your process, ensure batch-to-batch consistency, and accelerate your time to market with fully validated, turnkey solutions.

Pain Points We Solve

Navigating the Complex Challenges of

Pharmaceutical Processing

stringent cGMP compliance

Any deviation can lead to regulatory action, product recalls, and significant financial loss.

hazardous solvent handling

Process involves volatile solvents like ethanol, IPA, acetone require safe handling & efficient recovery.

reliable process validation

IQ/OQ/PQ validation is time-consuming, demands equipment design for seamless qualification.

Contamination

control

Prevents cross-contamination & ensures product purity. Oil-free operation & material compatibility are critical.

batch vs continuous flexibility

Systems must support both traditional batch & modern continuous manufacturing models.

Construction

Masonary Gallery

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Construction Management

Lorem ipsum dolor sit amet, consectetuer adipiscing elit

Civil Engineering

Lorem ipsum dolor sit amet, consectetuer adipiscing elit

Electrician Job

Lorem ipsum dolor sit amet, consectetuer adipiscing elit

Construction Laboring

Lorem ipsum dolor sit amet, consectetuer adipiscing elit

Plumbing

Lorem ipsum dolor sit amet, consectetuer adipiscing elit

Masonry

Lorem ipsum dolor sit amet, consectetuer adipiscing elit

Glazing

Lorem ipsum dolor sit amet, consectetuer adipiscing elit

Carpentry

Lorem ipsum dolor sit amet, consectetuer adipiscing elit

Painting

Lorem ipsum dolor sit amet, consectetuer adipiscing elit

Ironwork

Lorem ipsum dolor sit amet, consectetuer adipiscing elit

Elevator Installation

Lorem ipsum dolor sit amet, consectetuer adipiscing elit

Outsourced HR

Lorem ipsum dolor sit amet, consectetuer adipiscing elit

Our Approach

EcoProcess Solutions for Pharma

We engineer vacuum and process equipment specifically for pharmaceutical applications, ensuring regulatory compliance, product quality, and operational efficiency.

Validated by Design

Systems built for pharmaceutical cGMP compliance with IQ/OQ protocols and 21 CFR Part 11 compatible tracking.

Material-System Integrity

316L Stainless Steel for all product contact parts. Dry vacuum technology eliminates oil contamination risk.

Turnkey Solvent Recovery

Complete systems for distillation, evaporation, and drying with > 99% solvent recovery rates.

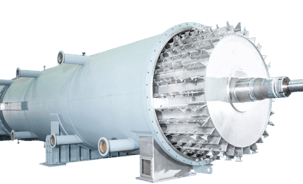

Equipment

Products for Pharma Applications

Drying Systems

Agitated Nutsche Filter Dryer (ANFD)

Filtration, washing, and drying of APIs in a single contained unit

Rotary Vacuum Paddle Dryer(RVPD)

Efficient drying of wet cakes under vacuum for sensitive products

Evaporation & Distillation

Advanced Vacuum Systems

Regulatory Compliance

Meeting Pharmaceutical Standards

cGMP Design

Equipment designed per FDA/WHO cGMP guidelines

ATEX, CE & PED

Solutions for flammable solvents & explosive atmospheres

IQ/OQ/PQ Support

Complete qualification documentation and validation protocols

Surface Finish

Ra ≤ 0.8 μm finish standard, electropolishing available

Material Traceability

Full material certificates (SS316L, Hastelloy) with 3.1 certification

99+

10-20%

Energy Savings vs. Conventional

99+

95%+

Solvent Recovery Rate

99+

99%

Product Purity Achievable

99+

12-18

Months Typical ROI

Case Study

API Manufacturer Achieves 95% DMF Recovery

Challenge:

A leading pharmaceutical company in Hyderabad needed to improve solvent recovery from their API drying process while meeting strict emission norms.

Solution:

EcoProcess installed an integrated ATFD system with solvent recovery.

Results:

95%

DMF Recovery Rate

14 Month

Payback Period

₹2.4 Cr

Annual Savings

100%

Emission Compliance

Questions

Frequently Asked Questions

How does EcoProcess support cGMP validation?

We design all pharmaceutical equipment according to cGMP principles with comprehensive IQ/OQ documentation and pilot plant for PQ validation.

What materials do you use for product contact parts?

Standard material is SS316L for corrosion resistance and cleanability. Hastelloy available for corrosive/high-temperature applications.

Can your systems handle flammable solvents like IPA?

Yes, we engineer solutions meeting ATEX safety standards with certified components and instruments.

Validate Your Process. Ensure Compliance. Accelerate Your Success.

Leverage our 99 years of engineering expertise and state-of-the-art pilot plant to design and validate the perfect solution for your pharmaceutical application.

Loy A Smith

Designer

Douglas L Johnson

Painter

Becky Smith

Grasshooper

Louis Carol

Manager

.png?width=303&height=227&name=wiped%20film%20evaporator%20(1).png)