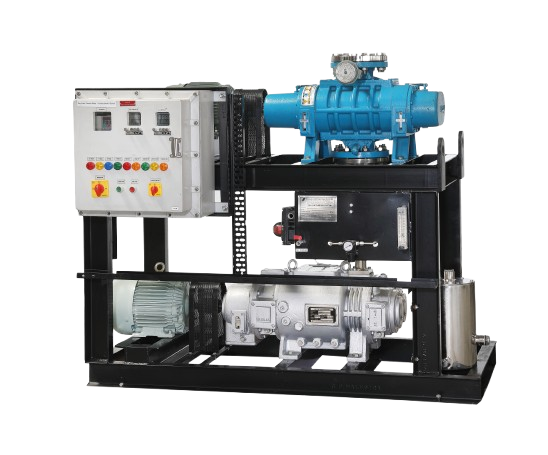

ENGINEERED MULTISTAGE VACUUM SYSTEMS

Custom-Built Dry Screw, Liquid Ring, Vane, Piston & Booster Combinations

Overview

EcoProcess engineered vacuum systems are fully customized, multistage solutions designed to meet the exact process, safety, corrosion, and performance requirements of chemical, pharmaceutical, agrochemical, food, and effluent-treatment industries.

Each system is built using validated process data — vapor load, condensables, solvent mix, temperature and pressure profiles, batch versus continuous operation, utility availability, corrosion considerations, and environmental requirements. Our engineering team configures the optimal combination of dry screw pumps, liquid ring pumps, rotary vane pumps, piston pumps, and vacuum boosters to deliver the desired performance with long-term stability and energy efficiency.

System Types

dry screw + booster system

High pumping speed and deep vacuum performance for solvent-rich, corrosive, and high-throughput processes.

liquid ring + booster system

Highly tolerant of wet gases, slurries, and condensables; ideal for filtration, distillation, and ETP applications.

hybrid liquid ring + dry screw systems

Combines the vapor-handling capability of liquid ring pumps with the deep-vacuum performance of dry screws.

rotary vane/piston-backed systems

Cost-effective solutions for utility vacuum and medium-depth process vacuum.

multistage booster trains

For high vapor loads, fast pump-down, & deep vacuum applications in resin/ polymer, chemical, & distillation processes.

Standard System Components

primary pumps

- Dry screw: EDPH, EDP

- Liquid ring: ELRC

- Rotary vane: WVS, KVA, KVAH

- Rotary piston: ET

secondary pumps

- ER series

- MKBM series

process equipment & safety blocks

- Knockout pots

- Condensers (shell & tube, surface, direct contact)

- Vacuum receivers

- Flameproof / ATEX motors

- Solvent traps

- Piping manifolds

- Condensate recovery lines

instrumentation & controls

- Pressure transmitters (PT)

- Temperature transmitters (TT)

- Flow transmitters (FT)

- Level transmitters (LT)

- Safety interlocks

- PLC–HMI with recipe-based control

- Alarms: high-temp, overload, seal failure, low vacuum

Applications & Benefits

applications

- Distillation and solvent recovery

- Reactor vacuum systems

- Falling-film and forced-circulation evaporators

- Vacuum dryers (tray, ATFD, Nutsche, cone)

- Degassing and de-aeration

- Vacuum filtration

- Crystallizers

- Polymer processing

- ETP vacuum systems

customer benefits

- Higher production output due to faster pump-down

- Lower operating cost (energy + maintenance)

- Longer equipment life

- Stable operation in corrosive or vapor-heavy environments

- Reduced downtime and improved process reliability

- Custom solutions for ZLD, solvent recovery, and hazardous duty

design & engineering

- Custom-designed based on process simulation and load curves

- Energy-efficient system architecture

- Optimized heat load and cooling water consumption

- Low noise and vibration profiles

- High uptime and minimal service requirements

- Modular skids for fast installation

- Corrosion-resistant metallurgy selection

- Explosion-proof and solvent-safe configurations

|

Model |

Pumping Speed (m³/hr) |

Ultimate Pressure (mbar) |

Motor Power (kW) |

Liquid Flow Rate (L/min) |

Weight (kg) |

|

ELRC 35 |

35 |

33 |

1.5 |

20 |

65 |

|

ELRC 65 |

65 |

33 |

3.0 |

30 |

98 |

|

ELRC 110 |

110 |

33 |

4.0 |

45 |

120 |

|

ELRC 160 |

160 |

33 |

5.5 |

60 |

165 |

|

ELRC 220 |

220 |

33 |

7.5 |

70 |

220 |

|

ELRC 300 |

300 |

33 |

11 |

80 |

280 |

|

ELRC 400 |

400 |

33 |

15 |

100 |

350 |