Process Solutions

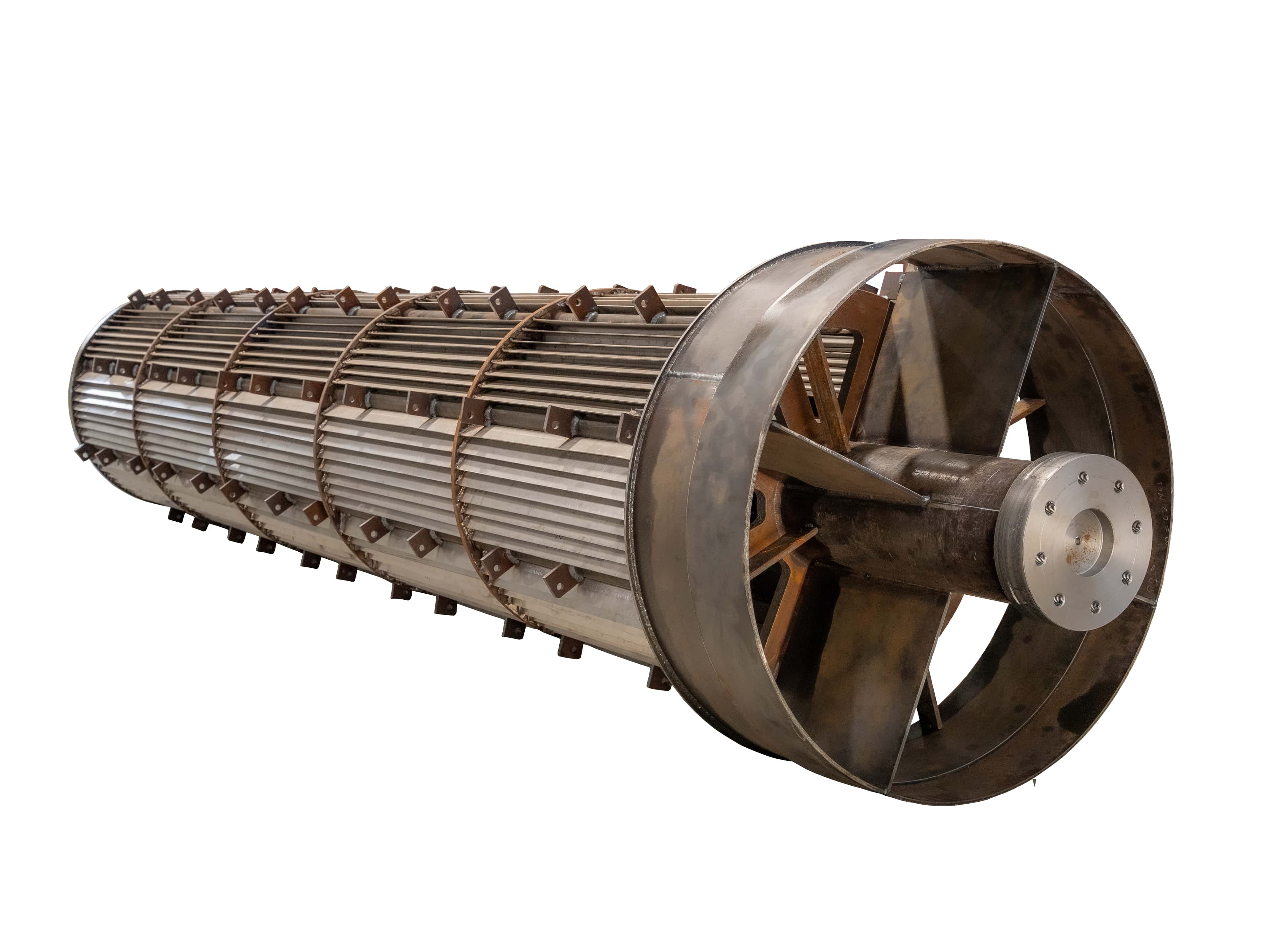

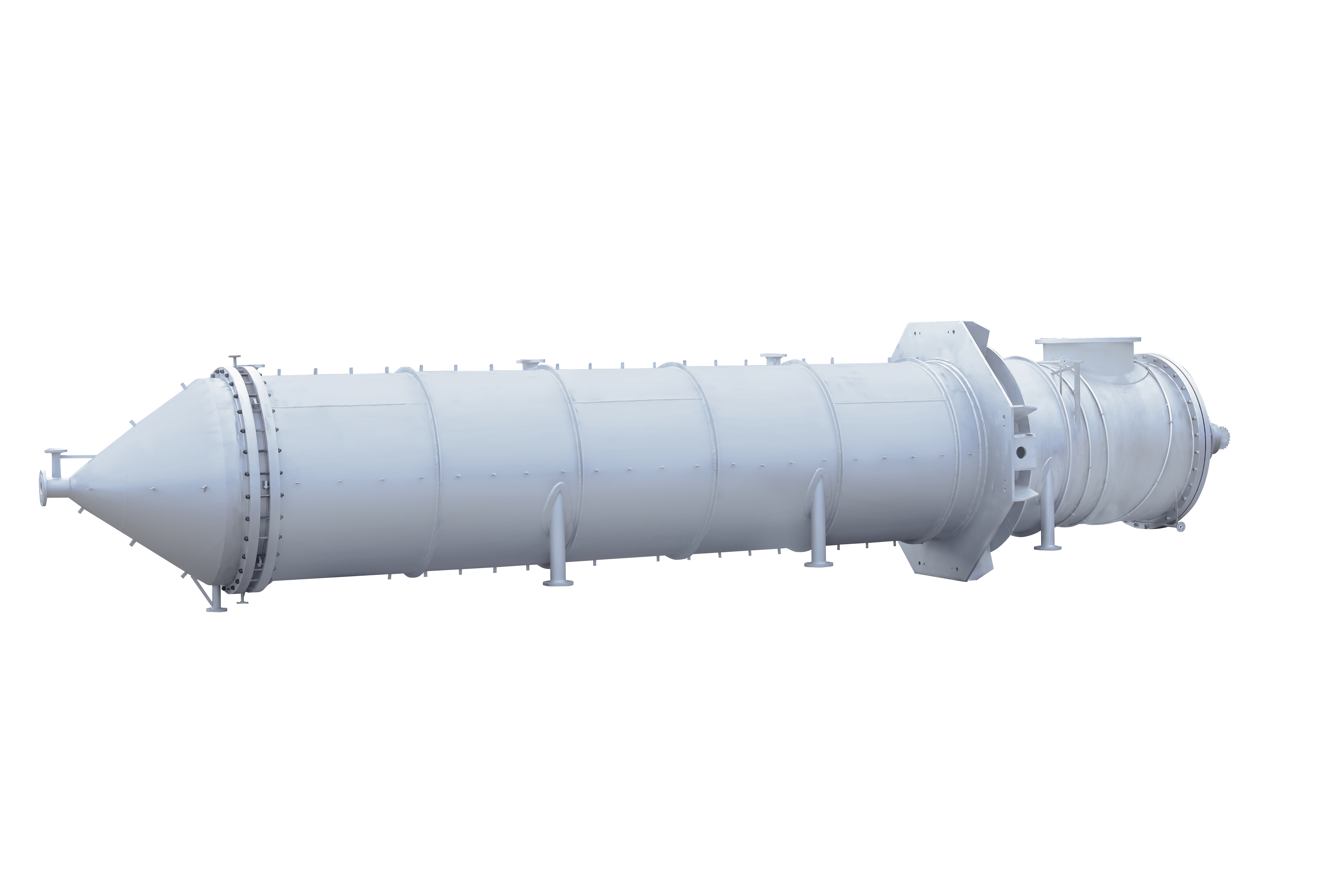

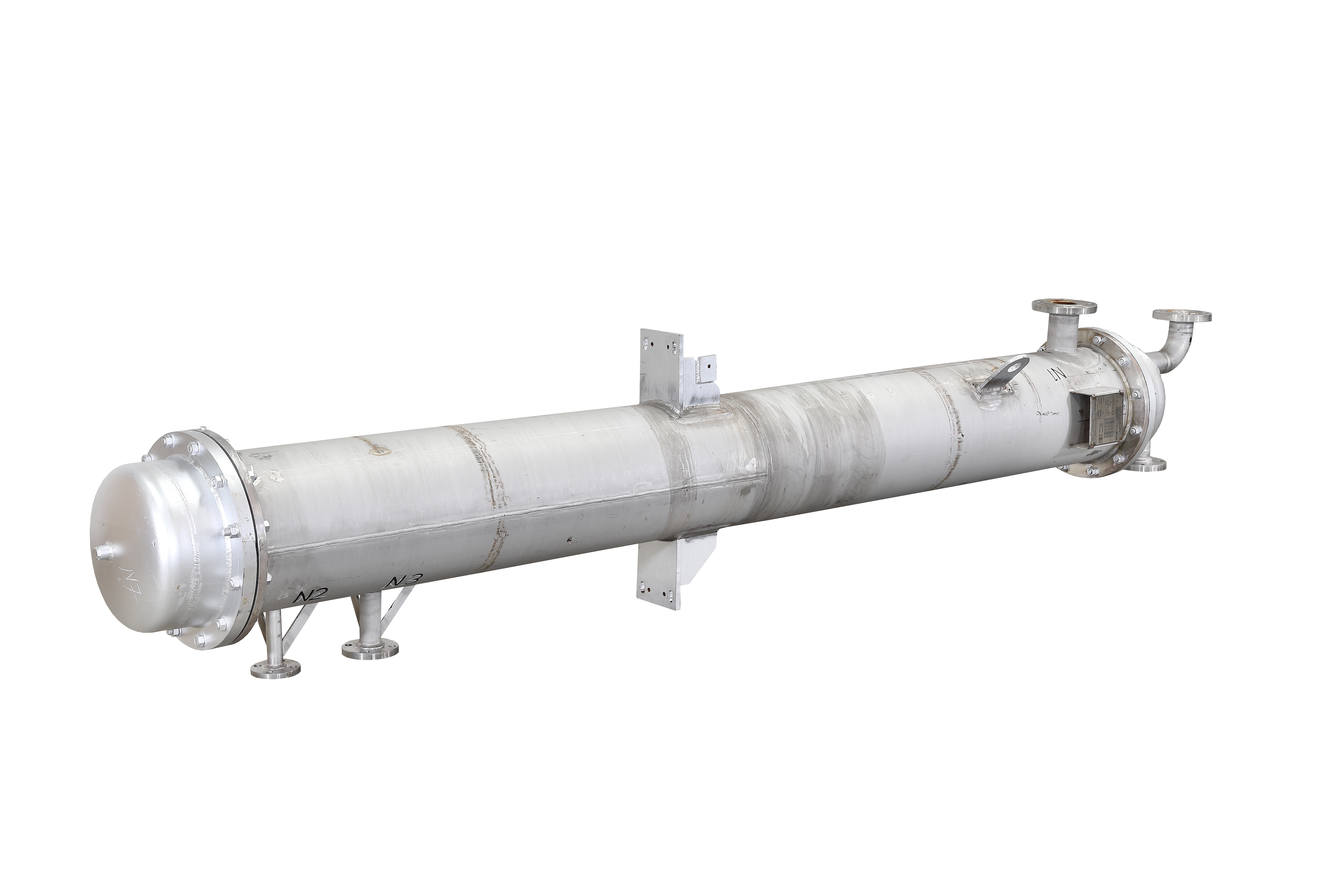

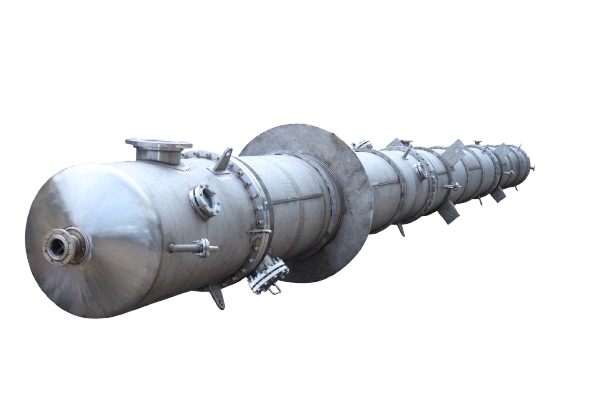

Economy Process Solutions offers a wide range of equipment for various industrial processes. From dryers for removing moisture to evaporators for concentration of liquids to heat exchangers for efficient transfer of heat, our selection of equipment is designed to provide efficient and cost-effective solutions for different processes. Additionally, we also offer process gear pumps for precise and accurate fluid transfer. With over seven decades of experience and expertise in the industry, we have the knowledge and capability to customize these solutions to perfectly fit the specific needs of our customers. Whether you are in the food and beverage, pharmaceutical, chemical or any other industry, we have the right solution for you. Our team conducts an in-depth study of your line and system needs during the design stage, and offers expert consulting on proper use and management of the equipment, tailored to your current and future installations. Trust us to streamline and optimize your process.

FAQ

What are process solutions?

Process solutions refer to the various methods, technologies, and equipment used to optimize and improve industrial processes. These solutions can be used to increase efficiency, reduce waste, improve product quality, and lower costs. Economy Process Solutions is the leading process equipment manufacturer in India

What are some common features of process equipment?

Some common features of process equipment include:

- Automatic controls and monitoring systems

- Safety features such as interlocks and alarms

- Adjustable settings to allow for process optimization

- Materials of construction suitable for the process conditions

- Ease of maintenance and cleaning

How can economy's process solutions improve efficiency?

Our process solutions can improve efficiency by reducing waste, streamlining processes, and increasing production capacity. For example, implementing a more efficient mixing system can reduce the time and resources required to mix materials, resulting in a more efficient process. High efficiency: Dry screw pumps have a high compression ratio and can achieve high levels of vacuum with relatively low power consumption. Low maintenance: Because they do not use lubricants, dry screw pumps have fewer moving parts and are less prone to wear, making them easier to maintain. Durability: The intermeshing screws of a dry screw pump are made of high-strength materials, making them resistant to wear and corrosion. Versatility: Dry screw vacuum pumps can handle a wide range of gases and vapors, making them suitable for a variety of applications.

Are process solutions always more efficient than traditional methods?

Some factors are driving the growth of the process equipment industry in India?

- Vacuum gauges to measure the pressure in the system

- Filters to remove contaminants from the air

- Automatic shut-off valves to prevent over-evacuation

- Safety interlocks to prevent accidental start-up

- Remote control or automation capabilities